Products

Contact now

- +86- 13794902396

- +86- 13794902396

- Amy@jubomg.com

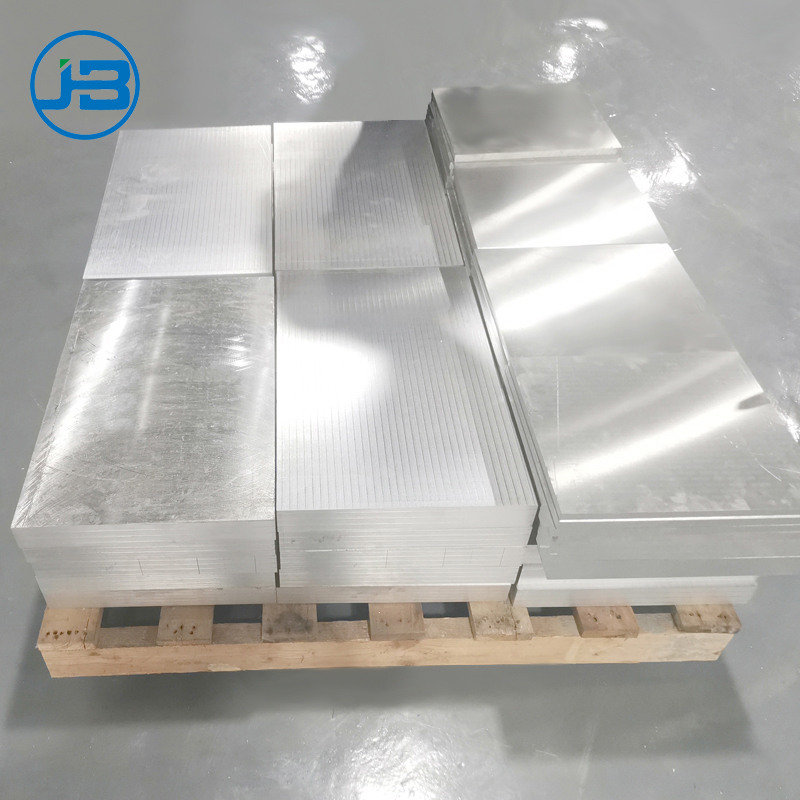

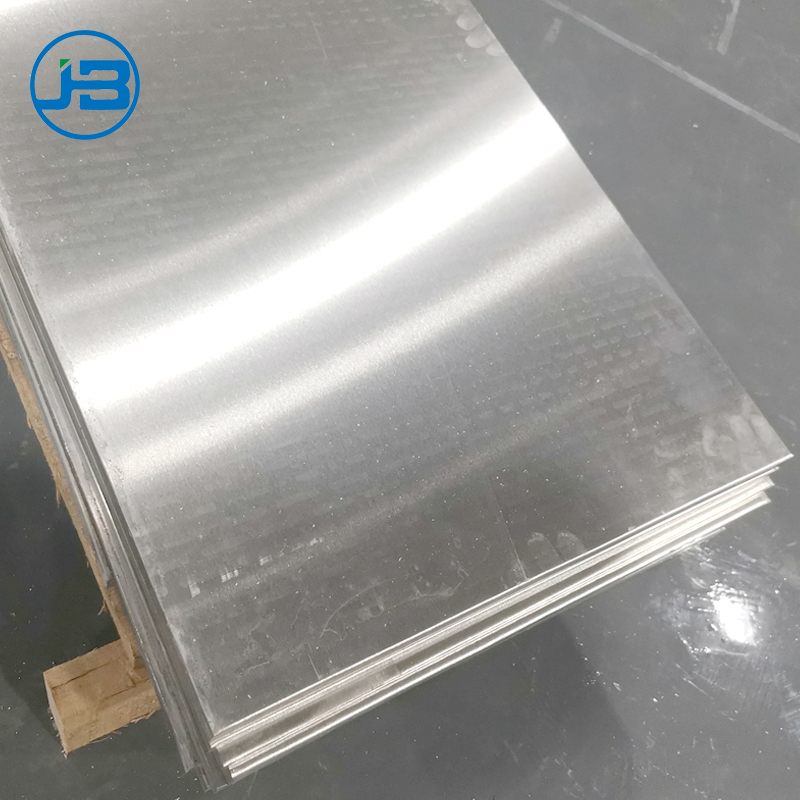

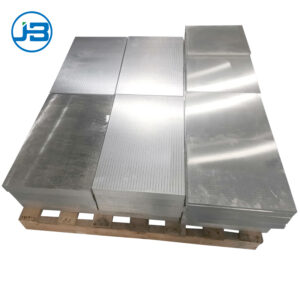

Customized magnesium alloy plate AZ91

Our factory mainly produces magnesium alloy sheets, magnesium alloy bars, magnesium alloy profiles, magnesium alloy tubes, magnesium alloy radiators, photoetched magnesium alloy sheets, etc., which are widely used in automotive parts, wheels, aerospace, 3C products (mobile phones, cameras, computers, etc.), machinery manufacturing and various aluminum alternative materials.

Customized magnesium alloy plate AZ91

Magnesium alloy grades are widely used in the automotive, aviation, and consumer electronics (3C) industries, such as mobile phone and car casings, and aircraft. These applications contribute to increasingly thinner phones and cars. In the automotive sector, lightweight materials are the optimal solution for reducing fuel consumption and exhaust emissions, driven by energy conservation and environmental protection. AZ31B sheet is suitable for medium-temperature applications below 150°F.Magnesium alloys are lightweight, high-strength, and highly rigid metal materials with excellent heat resistance and thermal conductivity. Therefore, they are widely used in aerospace, automotive, and machinery manufacturing. As a common form of magnesium alloy, sheet magnesium alloys are widely used in various industrial fields. Below, we will introduce some common sheet magnesium alloy grades.1. AZ31 Sheet Magnesium AlloyAZ31 sheet is a common sheet magnesium alloy composed of 3% aluminum, 1% zinc, and a small amount of manganese. This alloy exhibits excellent mechanical properties, corrosion resistance, and weldability. It has high strength and hardness, and good plasticity and machinability at room temperature. Therefore, AZ31 sheet is widely used in aerospace, automotive, and electronic equipment.2. AZ91 Sheet Magnesium AlloyAZ91 sheet is a magnesium alloy composed of 9% aluminum and 1% zinc. This alloy has high strength and corrosion resistance. Compared to AZ31, AZ91 sheet has higher heat resistance and low-temperature creep properties, making it suitable for applications in high-temperature and high-pressure environments, such as aircraft engine parts, automotive parts, and deep-sea exploration.

| Material | Magnesium | Type | Chip / Sheets / Plate |

| Application | High-speed Trains,ships,airplanes | Character | Thermal Conductivity |

| Operation | Thixotropic | Made | Sheet, Rod, Bar, Wire, Tube |

Features:

- Green material, good heat dissipation

- high strength, impact resistance,

- size stability and large elastic modulus,

- strong impact load capacity

- large vibration damping capacity

- stable performance in gasoline, kerosene and lubricating oil

Applications:

1. Magnesium alloy thick plates are used in the manufacture of satellite and lunar landing platform bases, missile and rocket outer panels, and missile and aircraft tail fins.

2. Magnesium alloy medium plates are used in the manufacture of rocket auxiliary fuel tanks, side panels, and other structural components.

3. Magnesium alloy applications in trains include suspensions, sleeper berths, sleeper linings, and brackets.

The width of front and rear panels and door panels of automobiles is required to be between 1200-1800mm, and the thickness is required to be between 1-1.5mm. Magnesium alloys are also widely used in 3C product casings, computers, mobile hard drives, CDs, cameras, audio equipment, and mobile phones.

In the printing and plate industries, magnesium alloy plates have replaced copper plates, with an average thickness of 5mm.

Chemical composition table

| Model | Mg | Al | Zn | Mn | Ce | Zr | Si | Fe | Ca | Cu |

| AZ31B | Bal. | 2.5-3.5 | 0.6-1.4 | 0.2-1.0 | – | – | ≦0.08 | ≦0.003 | ≦0.04 | ≦0.01 |

| AZ91D | Bal. | 8.5-9.5 | 0.45-0.90 | 0.17-0.40 | – | – | ≦0.08 | ≦0.004 | – | ≦0.025 |

| AZ61 | Bal. | 5.5-7.0 | 0.5-1.5 | 0.15-0.50 | – | – | ≦0.10 | ≦0.05 | – | ≦0.05 |

| AZ80 | Bal. | 7.8-9.2 | 0.2-0.8 | 0.12-0.50 | – | – | ≦0.10 | ≦0.005 | – | ≦0.05 |

| ZK61M | Bal. | ≦0.05 | 5.0-6.0 | ≦0.10 | – | 0.3-0.9 | ≦0.05 | ≦0.05 | – | ≦0.05 |

| ME20M | Bal. | ≦0.20 | ≦0.30 | 1.3-2.2 | 0.15-0.35 | – | ≦0.10 | ≦0.05 | – | ≦0.05 |

PERIODIC TABLE OF THE ELEMENTS

Q1: Can I order a sample quantity ?

A1: Yes, we have no MOQ.

Q2: Can I add my logo on the boxes/cartons?

A2: Yes,OEM and ODM are available from us.

Q3: What are the benefits of being a distributor ?

A3: Special discount Marketing protection.

Q4: How does your factory control the quality of your products?

A4: 100% self-inspection before packing. Quality is the life of our factory, first, each raw materials, come to our factory, we will test it first, if qualified, we will process the manufacturing with this raw materials, if not, we will return it to our supplier, and after each manufacturing step, we will test it, and then all the manufacturing process finished, we will do the final test before the commodities left our factory.